Case Studies

Please click on the quick link buttons below.

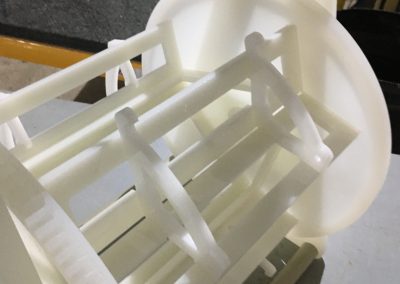

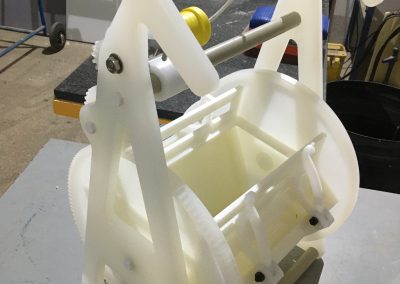

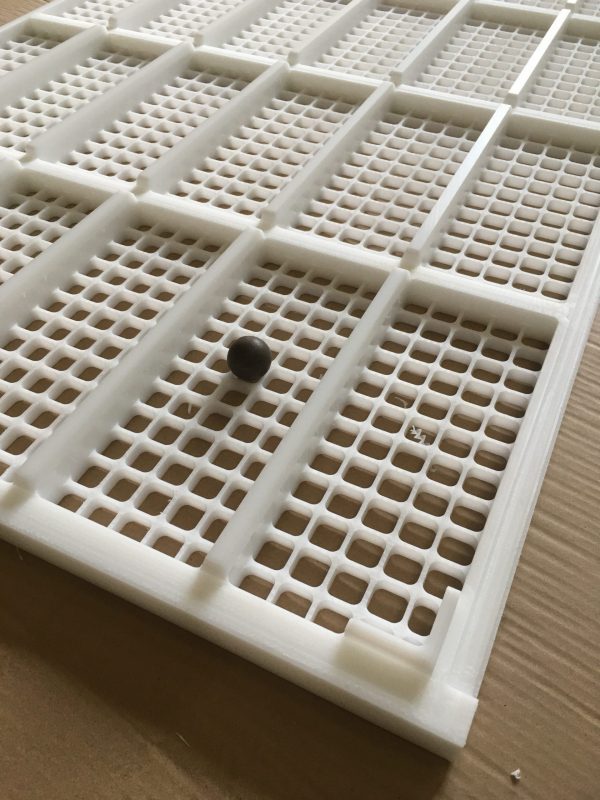

Grain Sieve Ball Cage

Our client offers industry-leading processing of grains, pulses and seeds to the highest standards typically required by supermarkets and food producers in the UK. The company has been operating since 1906, providing a service built on long experience, coupled with the latest in high-tech processing equipment.

Traditionally the ‘ball cage’ that cleans and sorts the grain is made out of oak. The process of processing the grain starts with spreading it over oscillating sieving decks, which remove dust, hulls and coarse impurities using air and sieves of various sizes.

In time the company needed to replace the traditional oak and wanted these highly specialised tools to be made out of plastic for hygiene and longevity reasons.

Saraco was able to exactly replicate the ball cages using state-of-the-art CNC routing equipment much to the delight of the local client.

” Mark is a very capable plastics engineer, he immediately grasped the essential function of the ball cage and the wider issues of food hygiene and combined this to come up with an excellent solution, transforming an elderly and decaying system into a modern system fully compliant with food requirements. I would highly recommend his services.“

Mark from Saraco explains in detail…

The selected sieve from a bank of over 200 different aperture sizes is clamped to a ball cage which has 24 separate zones, each zone containing rubber balls. The clamped assembly is loaded into a oscillating machine, during the oscillation process the rubber balls ricochet off the edges of the machined apertures and the angles sides upwards onto the underside of the sieve, the vibrations created aid the flow of seeds through the sieve.

The old ball cages are made in oak with a steel mesh fastened to it, these have been in service for about 30 years and were in need of replacement. With ever changing regulations the customer wanted to move away from wood and use a material suited to the food processing industry. Machining the unit from one piece of material would avoid the use of a steel mesh and associated fasteners, eliminate assembly, and maintenance associated with the old jointed system. Cleaning and sanitizing is easily carried out with modern chemicals and pressure washing, there are no seams and joints that will harbour bacteria.

Problem Solving

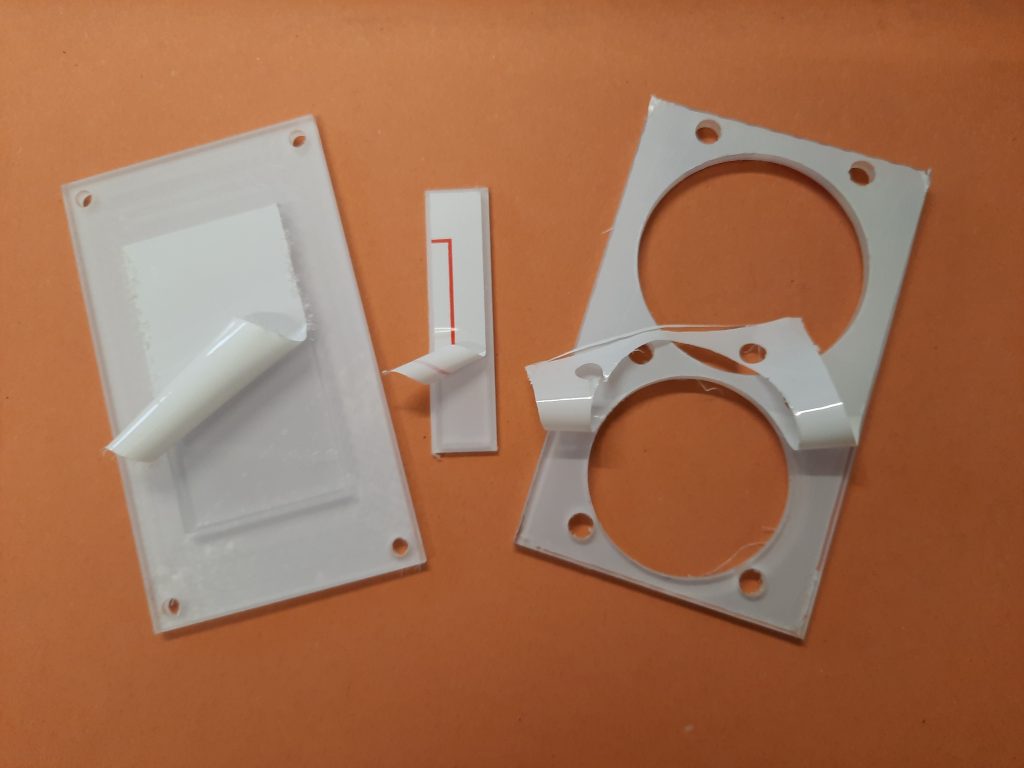

A Leading Technology Company

This technology company designs and manufacture high quality hermetic components & have been offering specialist plating services in the UK since 1969. Mark was asked to help solve a problem involving the specialist plating process where a combination of factors were affecting the baskets used to load the pieces to be plated.

He was able to create a bespoke solution in plastic for the company, who were so impressed, that they have subequently called on Mark’s services for solution ideas for other baffling and challenging problems that needed to be solved.

These have included bespoke work for an extraction system and designing and creating a duct system with valves to fit the unique angles of the building.

For a detailed look at one of the solutions provided click here.

For a closer look at more bespoke designs click on the images below.

“We used Saraco for an idea of Waste Water and Chemical Addition equipment.

We went to Mark with a sketch of our ideas. With his help and expertise, we managed to turn an idea into a piece of equipment perfect for the job and exactly what we imagined.

We found the whole process to be easy, cooperation was spot on and Mark was extremely helpful. 100% recommend to anyone. Thanks for bringing our idea to life.”

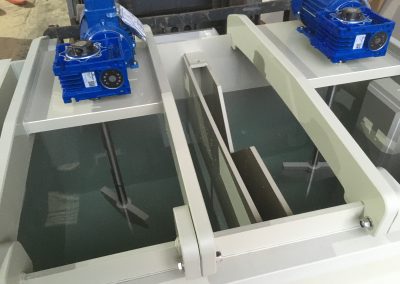

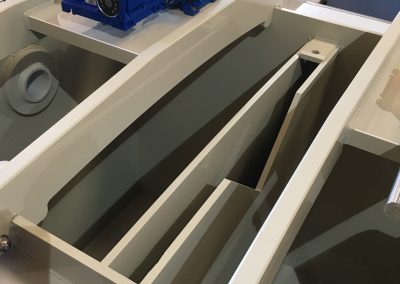

Chemical Tanks

Our client is an established company specialising in waste water asset management.

Dealing with waste water and its by-products from domestic and industrial streams requires both specialist knowledge and expertise to ensure that the waste product and effluent is dealt with correctly and to stringent environmental standards.

Mark designed and created a square tank with three different compartments for a pie factory in Crewe. This meant that the waste water could be fed into the tank, dosing fluids could be added and mixed into the effluent . When the right Ph is achieved the water can be safely released into the drainage system.

The tank had to be carefully welded as it needed to be weatherproof and very robust. The bespoke design includes two adjustable motor and paddles for mixing.

The business is investing in specialist, top of the range equipment, to make more chemical tanks. Please contact Mark if you are interested in learning what he can do to help.

For more photographs see below.

Plastic Fabrication

This client is a specialist sheet metal fabrication company operating from it’s modern and well-equipped premises in our local area. They needed Mark to design a plastic component required for display windows and optical displays.

Once the company started working with Mark, they have never looked back. The glowing testimonial speaks for itself!

“We approached Saraco when a very low volume plastic component was required. Our suppliers at that time were not interested in producing this and one who did quote, was extremely expensive. Mark came back with an acceptable quotation and lead time. The items were produced and consequently, we have used Saraco ever since.

Having previously worked as a supplier to Mark, we have no reservations about using him as a supplier to us. His attention to detail, technical knowledge and personal involvement ensures a product and service second to none.

We would have no reservations in recommending Saraco to anyone looking to have work carried out in the supply of plastics and plastic fabrication field.”

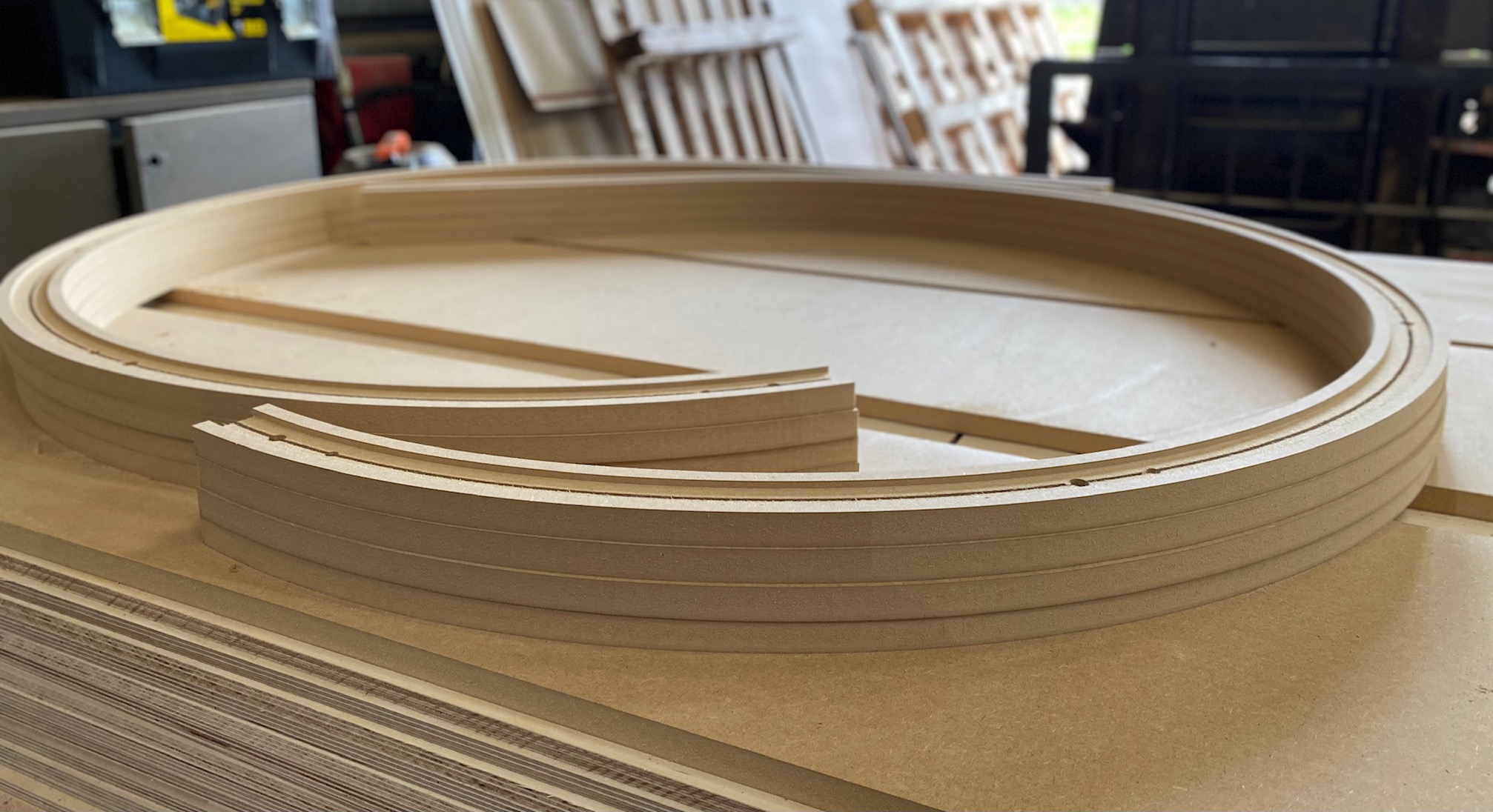

Wood cutting

Our client is a leading UK manufacturer of innovative office, reception and meeting room furniture, storage solutions and library furniture. The company have machines to produce the furniture themselves, but when things get busy they are able to rely on Saraco to support their business by producing the components in good time.

Mark has an excellent relationship and works closely with the company. He has been able to advise on cutters and useage and is the preferred supplier.

Specialist Dust Extraction

This client produces PCBs (printed circuit boards) in a dry, ecological and economical way. PCB prototyping equipment is specially designed for schools, universities and laboratories to make teaching as efficient as possible. However, drilling the boards is hazardous as the dust created would be harmful to breathe. Normal vacuum cleaning products were not able to withstand the constant use required in this manufacturing environment.

Mark has designed a 24 hour dust extractor which includes a hepa filter and side channel blower technology.